Laboratories

The Laboratory for Development of Custom-Made Implantas

Prof. Svatava KonvičkováHead:

Workers:

Prof. Svatava Konvičková , Ing. Pavel Růžička, Ph.D.

Description:

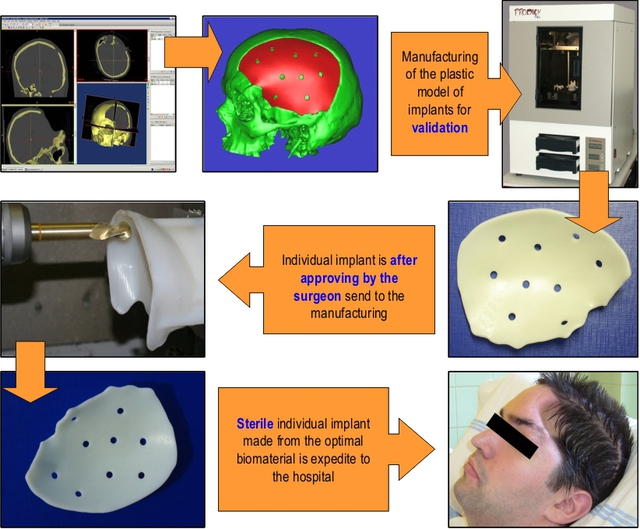

The goal of reconstructing skeletal defects using custom-made implants is achieving the full function and absolutely natural appearance for the patient. There are efforts to replace lost anatomical structures, restore reduced function and, in case of aesthetic surgery, to improve the visual aspect for the patient. Currently, the worldwide trend in production of artificial prostheses is inclined to customization of artificial implants for individual patients instead of unified sizes and shapes. The scope of application of such approach may be found in a number of medical areas: neurosurgery, maxillofacial surgery, orthopedics, and also aesthetic surgery. Other possible areas of successful application of such methodology are the following: archaeology (reconstruction of skeletal remains – modeling), criminological practice (reconstruction of skeletal remains – models of injuries), medicine (making of geometrical models, plastic phantom models for preparation of surgeries), etc.

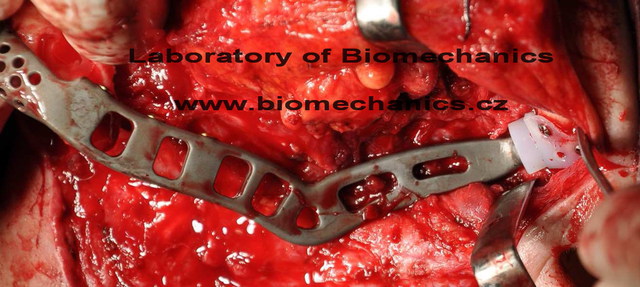

While solving a number of clinical cases we managed to devise a fast, accurate and effective method of designing and fabrication of custom-made skeletal prostheses using suitable, commonly used biomaterials, which may be used to replace the defected area. We used this method to realize several clinical studies illustrating fabrication of such custom-made prostheses together with post-surgery X-ray verification.

For effective design and fabrication of custom-made prostheses, close cooperation between doctors, the manufacturer, and the patient is vital. This cooperation depends especially on thorough examination of the patient, high-quality diagnostic imaging of the defect, correct indication and choice of treatment, and perfect operational and prosthetic treatment. Close cooperation between the surgeon, technician, manufacturer, and the patient is essential not only during the treatment itself, but also during following patient’s convalescence and rehabilitation. For a long time, our workplace has been successfully cooperating on development and fabrication of custom-made prostheses with local manufacturers of medical devices – ELLA CS s.r.o. and DUO CZ s.r.o., which comply with all legislative requirements applying to manufacturers in the Czech Republic and EU (ISO 13485).

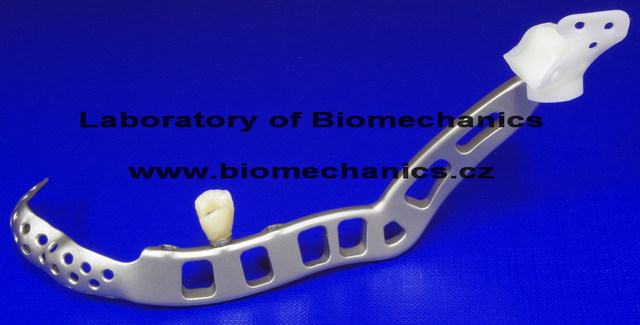

For custom-made implants, with regards to medical and technology requirements, the available materials are metallic (titanium Ti6Al4V ELI, surgical steel) and plastic (PEEK, UHWMPE). The following text states some standard clinical applications of the design and fabrication of custom-made prostheses.

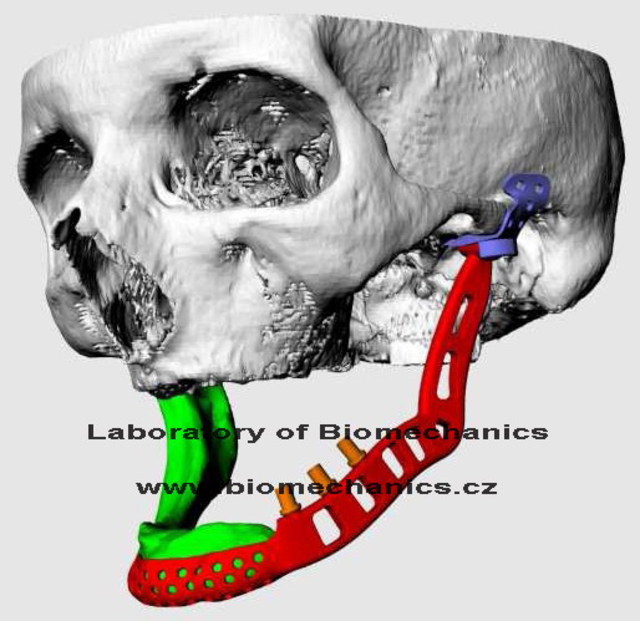

- Maxillofacial surgery

In this area, the custom-made implants may be used for reconstruction of complicated shapes, large and possibly loaded bone tissue defects. The prostheses may be applied especially for replacement of defects as a consequence of oncology treatment, large post-injury conditions, etc. The advantage is the possibility to design the implant not only in the way that it corresponds with the original condition, but also that the suitable prosthetic treatment can follow immediately.

- Neurosurgery

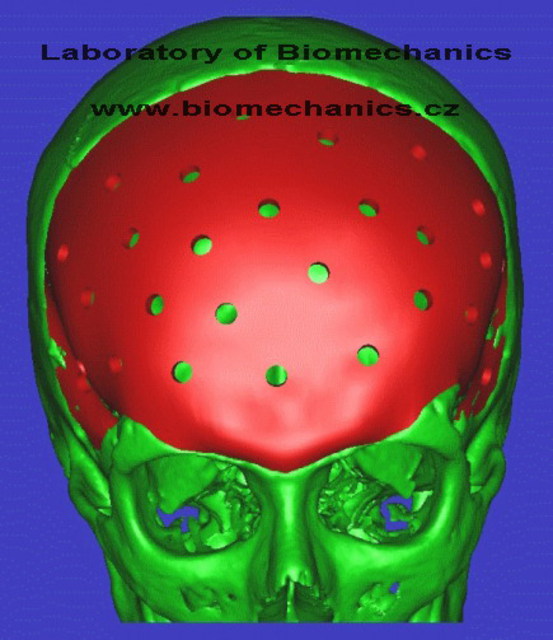

The example of using custom-made prostheses may be aesthetic cranio surgery, when large bone defects must be replaced and it would be difficult to apply conventional materials (PMMA, Medpor). The main advantage, in comparison with conventional prostheses, is the precise shape of implant, higher load and pressure resistance, and lower weight (especially for large defects).

- Orthopaedics

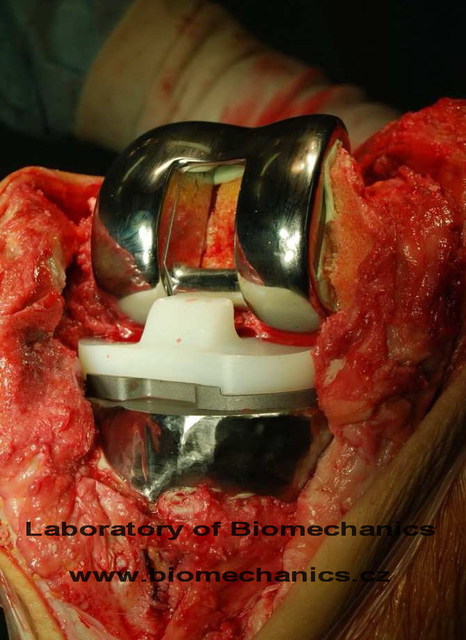

The custom-made implants are in this area used only marginally – primarily together with conventional prostheses when treatment of large defects may be difficult using only these prostheses, e.g. for joints. The advantage of this method is the possibility to adapt the shape of custom-made implants so that they supplement the conventional prostheses. The custom-made implants may improve the transfer of load impact on bone tissue, and consequently reduce the risk of conventional prostheses failure.

Videos:

publications:

- Jirman R, Vavrik P, Horak Z: Custom-Designed 3D Tibial Augmentation for Knee Replacement. Acta chirurgiae orthopaedicae et traumatologiae Cechoslovaca, 2009, 76(1), 60-64

- Jirman R, Horak Z, Mazanek J, et al.: Individual 3D Replacements of Skeletal Defects. 2009, 13TH INTERNATIONAL CONFERENCE ON BIOMEDICAL ENGINEERING, VOLS 1-3, Book Series: IFMBE, Proceedings, Volume: 23, Issue: 1-3, Pages: 1228-1231.

- Horák Z., Jirman R.: Custom made implants of the sceletal defects. Lékař a technika. 2008, 38(4), 65-70.

- Jirman R., Horák Z., Mazánek J.: Custom made implants of the sceletal defects. Časopis České stomatologické komory LKS. 2009, 19(12), 374-378. (in Czech).

- Jirman R., Horák Z., Mazánek J., Řezníček J.: Individual Replacement of the Frontal Bone Defect: Case Report. Prague Medical Report. 2009, 110(1), 79-84.

Cooperation:

DUO CZ, s.r.o.; ELLA-CS, s.r.o.

Stomatology clinic 1LF UK a VFN (Radek Jirman, MD; Prof. Jiří Mazánek, MD, PhD); Department of Orthopaedics, 1st Faculty of Medicine and Motol Teaching Hospital (Pavel Vavřík, Associate Professor); Neurosurgical department of 1st Faculty of Medicine of Charles University, Institute of Postgradual Medical Education and the Central Military Hospital in Prague (Jaroslav Plas, MD, PhD, Associate Professor); Department of Neurosurgery, Krajská nemocnice Liberec, a.s. (Pavel Buchvald, MD)

Projects in realisation

- Research of technical and biological composite materials

- Indentor instrument for cartilage stiffness measurement

- Mathematical model of a lower extremity focused on a knee joint

- Simulation of cyclic loading of total knee replacement where an evaluation of cyclic stress state in tibial plateau is ephasized

- Endurance Test of Stemmed Femoral Component of Total Hip Replacement

- Long Bone Reconstruction and Periprosthetic Fractures Using the Osteosynthesis Materials and the Operation Procedures - Trauma I

- Inovation of French Crutches

- Mechanical properties of osteoporotic bones

- Optical 3D coordinate measuring machine

- Mathematical model of a lower limb featuring an oncology hinge type knee endoprosthesis

- Apllication of ceramics and β-Ti alloy for shoulder endoprostheses

- Revision Endoprosthesis of Acetabulum - FEM Analyses of the augmented replacement.

- The development of intelligent endoprosthesis with automatic early detection of potential failure