Dentální a orofaciální systém

Výpočtové analýzy a experimentální testy dentálních implantátů

Popis projektu:

Shématické vyobrazení dentálního implantátu.

Dentální implantáty

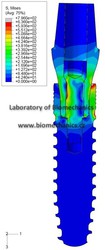

MKP analýza modelu dentálního implantátu

Prototyp implantátu upnutý v přípravku před testováním.

Problematika dentální biomechaniky je na našem pracovišti řešena již od roku 1996 a to v rámci úspěšné spolupráce s většinou tuzemských výrobců dentálních implantátů (Lasak s.r.o., Dentamechanik s.r.o., Medin Orthopaedics a.s., atd) a řadou klinických pracovišť (Výzkumný ústav stomatologický 1LF UK a VFN, Stomatologická klinika 1LF UK a VFN atd.). V současné době je naše pracoviště schopno provést pevnostní výpočtové MKP analýzy libovolných typů dentálních implantátů a na základě výsledků z těchto analýz navrhnout konstrukční změny konkrétního implantátu. Výsledky MKP analýz jsou velmi závislé na kvalitě vstupních dat (velikost žvýkacích sil, materiálové parametry kostní tkáně, atd.) a proto byla vyvinuta celá řada dílčích postupů, jejichž cílem byla minimalizace vstupních chyb:

- „In vivo“ měření kinematiky žvýkání: na našem pracovišti byla vyvinuta metodika „in vivo“ měření kinematiky žvýkání a stanovení velikosti a směru žvýkací síly. Touto metodou byla pořízena série dat kinematiky pohybu dolní čelisti a stanovení skusových sil pro různé umístění sousta a různou tvrdost žvýkaného sousta. Tato data lze využít jako vstupní data do MKP analýz.

- Materiálové modely kostní tkáně dolní čelisti: na našem pracovišti byla také vypracována metodika tvorby prostorového modelu lidské čelisti z CT snímků a to včetně heterogenních materiálových charakteristik získaných z hodnot stupně šedi jednotlivých snímků. Tímto způsobem lze dojít ke zpřesnění výsledků všech MKP analýz modelů dentálních implantátů.

V současné době je naše pracoviště také schopno provést i mechanické testování prototypů dentálních implantátů dle mezinárodní normy ČSN EN ISO 14801:2008 - Dynamická únavová zkouška nitrokostních dentálních implantátů. Cílem prováděných zkoušek je vytvoření únavového diagramu a stanovení mezního únavového zatížení - tj. maximální cyklické zatížení, při kterém implantát vydrží 5 mil. cyklů. Dalšími stanovovanými hodnotami jsou mezní statické zatížení a maximální ohybový moment dosažený při mezním únavovém zatížení nitrokostního implantátu.

Ing. Tomáš Goldmann PhD ; doc. Ing. Radek Sedláček, Ph.D.Řešitelé:

Dentamechanik s.r.o.; LASAK, s.r.o.; Medin Orthopaedics, a.s.

Spolupráce:

Literatura:

- Goldmann T., Himmlová L., Aleksic Z., Ihde S.: The Use of Finite Element Analysis to Model Bone-Implant Contact with Basal Implants. Oral Surgery, Oral Medicine, Oral Pathology, Oral Radiology, and Endodontology. 2008, 106(1), 309-316.

- Goldmann T., Ihde S., Kuželka J., Himmlová L.: Bendable vs. Angulated Dental Implants: Consideration of Elastic and Plastic Material Properties Based On Experimental Implant Material Data and FEA. Biomedical Papers. 2008, 152(2), 309-316

- Ihde S., Goldmann T., Himmlová L., Aleksic Z.: The Use of Finite Element Analysis to Model Bone-Implant Contact with Basal Implants. Oral Surgery, Oral Medicine, Oral Pathology, Oral Radiology, and Endodontology. 2008, 106(1), 39-48

- Ihde S., Goldmann T., Himmlová L., Aleksic Z., Kuželka J.: Implementation of Contact Definitions Calculated by FEA to Describe the Healing Process of Basal Implants. Biomedical Papers. 2008, 152(1), 169-173

- Bouda T., Horák Z.: Numerical FE analyses of the dental implants MEDIN. Praha: ČVUT FS, Ústav mechaniky, Laboratoř biomechaniky člověka, 2009. 12105/09/06. 9 s. (in Czech).

- Himmlová, L., Dostálová, T., Kácovský, A., Konvičková, S.: Influence of Implant Length and Diameter on Stress Distribution: a Finite Element Analysis. The Journal of Prosthetic Dentistry. 2004, vol. 91, no. 1, s. 20-25.