Musculoskeletal system and artificial replacements

Research on tissues and body structures and biomaterials

Medical and health applications

Experimental equipment

The corrosive potential as a marker of endoprosthesis failure

Project description:

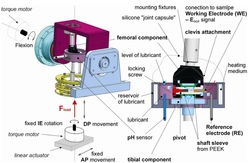

Experimental setup

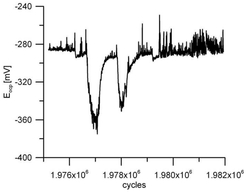

The figure shows part of the open circuit potential as recorded for the implant coated with a DLC layer. Its repeated decrease by about 100 mV is clearly evident at the simulator reaching 1.9766 x10^6 loading cycles. This testifies to a local damage of the surface which, however, was eliminated by the system – the increase corresponded to the damaged surface repassivation.

Visual inspection of contact surfaces on knee endoprosthesis is very time consuming. Loading must be interrupted, join capsule must be removed, some simulator components must be disassembled as well as endoprosthesis components. Moreover it is necessary to assemble all components after inspection carefully and accurately before another loading. On the other hand, it is appropriate to have a possibility to inspect contact surfaces immediately after failure initiation. While testing real components, it is usually impossible to fix the time of the damage initiation and then interrupt the test in order to evaluate the implant state.

Online monitoring of open circuit potential (Eoc) (corrosive potential) seems to be an applicable method for checking failures on replacements surfaces. Titanium prosthesis are self-coating by passivating layer. If something scratches the layer, Eoc sharply changes in the order of several hundreds of millivolts.

The measurements were performed using the Magic XBC E (Gryf HB) system allowing to record the open circuit potential, temperature and the pH value of the exposure environment.

Special hinge-type knee prosthesis is used for testing. This prosthesis consists of tibial and femoral component, cilindrical pivot (made from titanium alloy, coated by DLC layer), PEEK shaft sleeves and locking screw. The Eoc was measured against a silver - silver chloride - chloride electrode (Ag / AgCl / KCl 3mol / L).

Ing. Jakub Kronek Ph.D.Resesrchers:

ProSpon company

HVM PLASMA company

The Institute of Chemical Technology, Prague (ICT)