Experimental equipment

Digital 3D Correlation Systém Q-450

Project description:

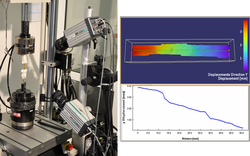

Uniaxial tensile test - 3D.

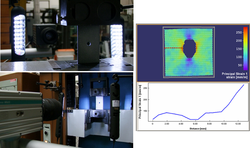

Uniaxial tensile test - 2D.

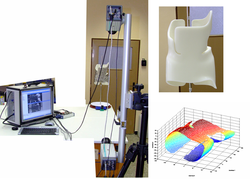

Scan corset - 3D.

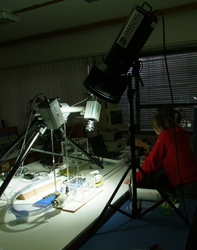

Detection of pulse wave velocity and the inflation test.

Detection of pulse wave velocity and the inflation test.

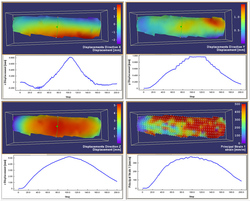

The Digital 3D Correlation System Q-400 is used for non contact, full field measurement of contour and deformation of any object. It consists of two high resolution CCD cameras, an illumination device and an evaluation computer with software. Condition is natural or artificial stochastic pattern on the surface of the material. This pattern is observed by the one (2D) or the two (3D) cameras. The deformations and distortions of this pattern due to deformation or movement of the object are recorded by the cameras. These images are automatically analysed with special high accuracy correlation algorithms. The result a set of data is generated containing the start contour of the object at beginning of the measurement and the threedimensional displacement vector of each object point due to the object deformation. Furthermore, the surface strain components are derived at every surface point. System before the measurement must be calibrated using calibration targets. You can then evaluate the displacement of each point of the surface sub-pixel accuracy. Consequently, strains as small as 0.01 % can be resolved. On the other hand, also very large deformations with strains of several 100% can be analysed. Various data export functions deliver the interfaces for further data processing in external program systems.

Technical data

- Mobile system

- Measurement area: some mm² up to m², now are 5 x 5 mm² up to 300 x 300 mm²

- Measuring results: 3D surface contour, 3D displacements, strains at every measured point

- Measuring range: from 100 μStrain up to several 100% Strain

- Integrated analogue data acquisition and recording input: 8 independent free-selectable analogue Data Acquisition Channels, 16 Bit resolution

- ± 0.05 V to ± 10 V synchronized to camera triggering

- Camera type: Nanosense Mk III, sensor chip CMOS, 1280 x 1024 pixel, 10 bit CMOS, 512 x 512 pixel, 10 bit

- Measuring sensitivity: Displacement - up to 1/100.000 of the field of fiew depending on measuring conditions.

- Measuring sensitivity: Strain - up to 0.01% local

- Resolution / Frame rate (fps) [Hz] - 1280 x 1024 / 1040, 1280 x 640 / 1660, 1280 x 320 / 3330, 1280 x 80 / 13100

- Data recording: memory configuration: 1GB. (optional: 4GB)

- Longer recording times depending on sensor resolution and frame rate

- Shutter times: 1000 ns – 100 ms

Equipment is available in the Laboratory of Cardiovascular Biomechanice, contact person Ing. Hynek Chlup