Laboratories

Mechanical Testing Laboratory

doc. Ing. Radek Sedláček, Ph.D.Head:

Workers:

Ing. Jakub Kronek Ph.D., Ing. Adam Kratochvíl , Kristýna Kubášová

Description:

The Mechanical Testing Laboratory (MTL) is a workplace at the Czech Technical University in Prague, Faculty of Mechanical Engineering, and is attached to the Department of Mechanics, Biomechanics and Mechatronics. The laboratory was constructed within the scope of grant-funded project VS 96045 of the Ministry of Education of the Czech Republic "Laboratory of Biomechanics" and research plan "Transdisciplinary Research in the Field of Biomedical Engineering" CEZ: J98210000012.

Equipment in MTL:

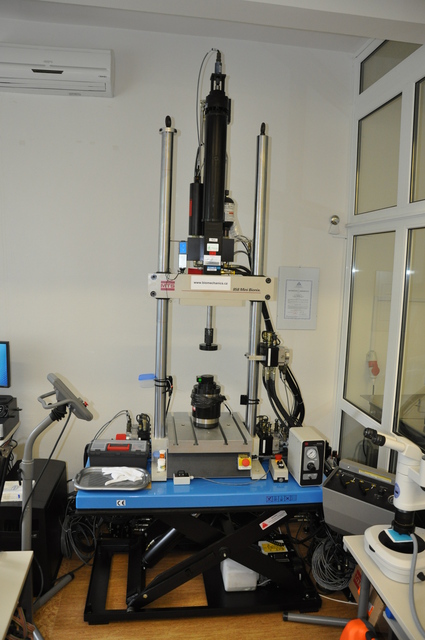

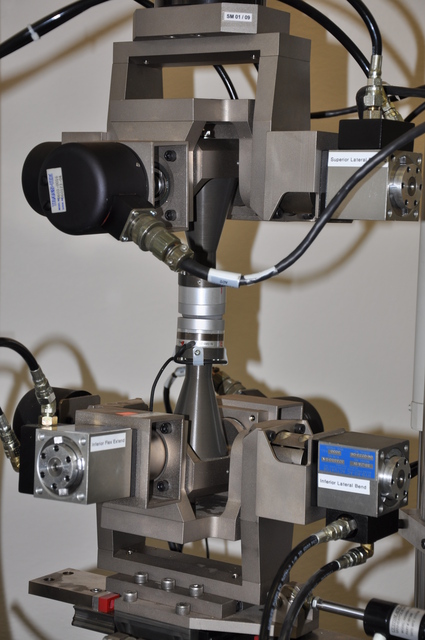

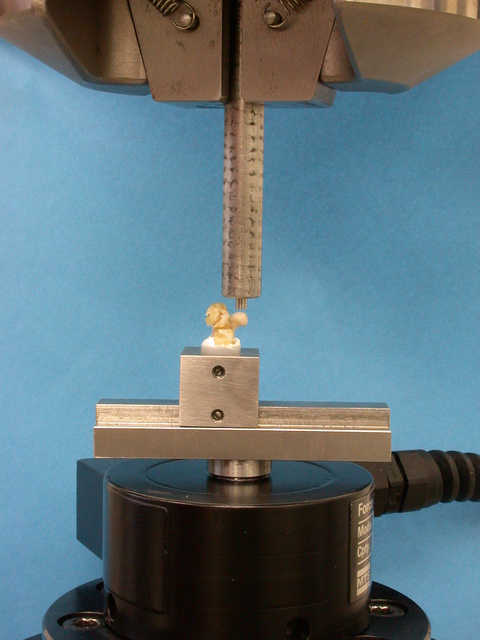

- The MTS 858.2 MINI BIONIX testing system (Figure 1) is the main device in this laboratory. It enables loading with axial load and torque. The testing system has an axial load range of 0 ÷ 25 kN. The torque is in the range 0÷100 Nm. It is now invested with a special simulator (Figure 2a) that enables loading with 8 degrees of freedom (3 displacements and 5 rotations). This simulator is unique in Europe. Iťs construction is designed for difficult spinal testing. After modification, this simulator can be used for other experiments.

- Special MTS load transducers for measuring very low forces in the axial load range ±10/100/500/25000 N

-

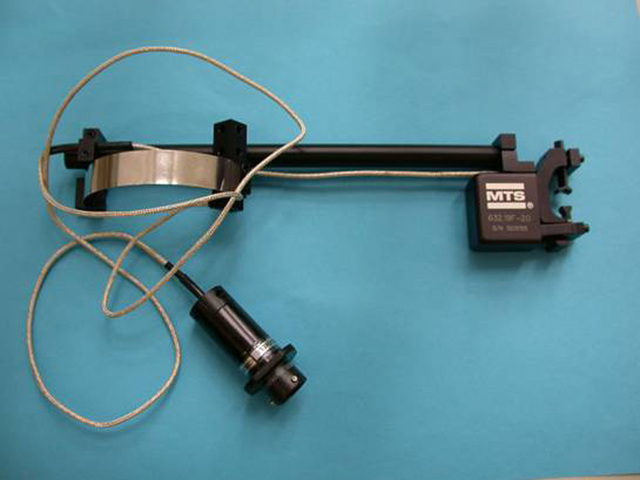

An extensometer with a range of ± 0.4/4 mm (Figure 2b), special bioextensometer with a range of ± 25%, lo = 5 mm –

-

for evaluating elongation (Figure 2c);

-

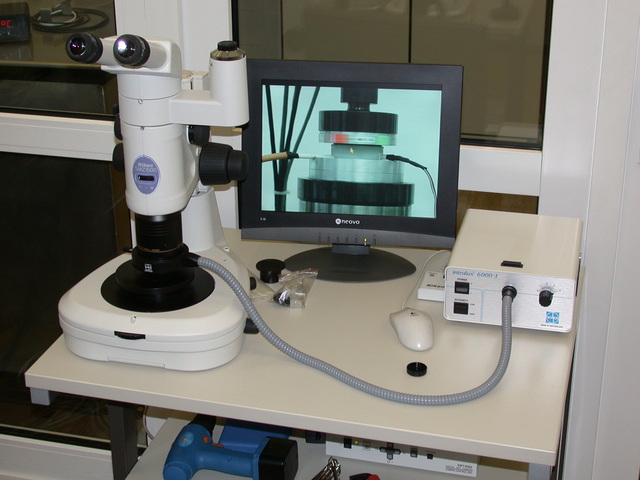

A NIKON SMZ 1500 stereomicroscope (Figure 2d), used for observing specimens. It ensures high-quality exploration of surfaces, fractures and structures of specimens; a NIKON DN100 digital camera, microsonde VOLPI (Figure 2e) and LUCIA NET evaluation software for recording and image processing from the stereomicroscope

-

A FLUKE 574 infrared contactless thermometer

MTL is the testing laboratory No. 1379 accredited by CAI according to ČSN EN ISO/IEC 17025:2018 (s. Certificate of Accreditation). The CAI periodical check on observance of the accreditation criteria leads to ongoing developement of the quality management system, raises service quality, enhances the skills of the staff and contributes to better technical provision of the laboratory. MTL is the sole accredited laboratory in the Czech Republic for mechanical testing and surveying of bioceramic materials for surgical implant production (s. Appendix to Certificate of Accreditation).

MTL has 14 accredited testing methods:

-

ZP 01 – Determination of bending strength – ASTM F382, p. 7.2.1 and ISO 9585(E) (bone plates)

-

ZP 02 – Determination of bending strength - ČSN EN 843-1 (ceramics)

-

ZP 03 – Determination of bending strength - ČSN EN ISO 13356, p. 4.6; ISO 6474-1, p. 6.4.3; ISO 14704; ČSN EN ISO 6872, p. 7.3.1; ASTM C1161 (ceramics)

-

ZP 04 – Determination of biaxial bending strength - ČSN EN ISO 13356, p. 4.5; ISO 6474-1, p. 6.4.2; ASTM C1499 (ceramics)

-

ZP 05 – Bending fatigue test – ČSN EN ISO 13356, p. 4.10; ISO 6474-1, p. 6.9; ISO 22214 (ceramics)

-

ZP 06 – Bending fatigue test – ČSN EN ISO 14801 (dental implants)

-

ZP 07 – Bending fatigue test – ČSN EN ISO 11334-1, p. 5.6, p. 5.7 (elbow crutch)

-

ZP 08 – Bending fatigue test – ASTM F382, p. 7.2.2 (bone plates)

-

ZP 09 – Bending fatigue test – ASTM F1264, p. 6.3.1, 6.4.1, 6.5.1 (Intramedullary Fixation Devices)

-

ZP 10 – Bending fatigue test – ISO 7206-4 (Femoral stem)

-

ZP 11 – Bending fatigue test – ISO 7206-6 (Femoral neck)

-

ZP 12 – Bending fatigue test – ČSN EN ISO 21536 (p. 7.2.1), ISO 14879-1, ASTM F2083 (p. 6.3.1), ASTM F1800 (Tibial tray)

-

ZP 13 – Static test – ISO 7206-10 (Femoral head)

-

ZP 14 – Wear test – ČSN EN ISO 21536 (p. 7.2.2), ISO 14243-2, ISO 14243-3 (Knee-joint prosteheses)

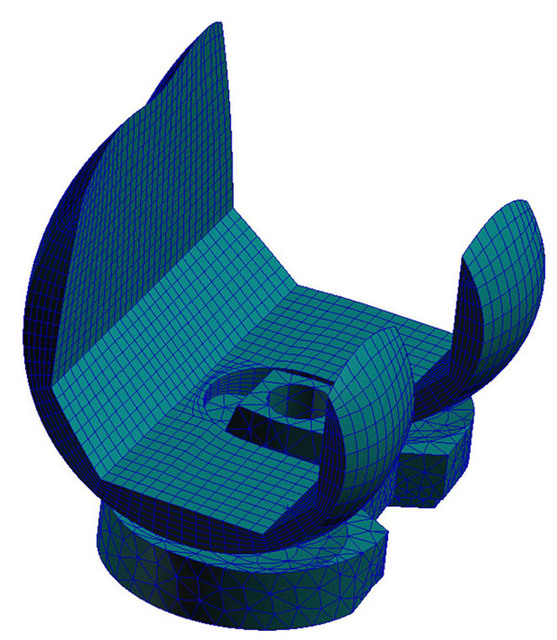

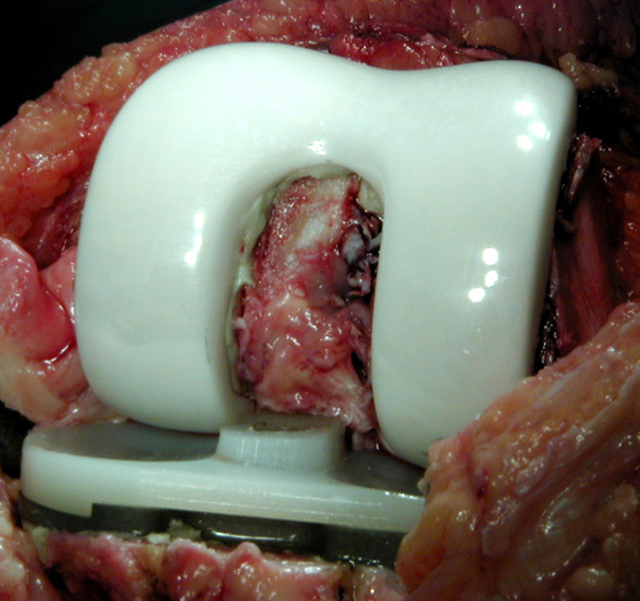

Specially designed ceramics for producing a new type of knee replacement with a bioceramic femoral component (Figure 3) were tested in MTL in accordance with most of the test procedures listed above. This development took place in the Laboratory of Biomechanics (LBČ) in cooperation with the Walter, Inc., Saint-Gobain Advanced Ceramics Turnov, Ltd., and the First Faculty of Medicine, Charles University in Prague. This bioceramic knee component was the first in the world to complete clinical tests. In 1999, LBČ won an innovation prize for this proposal, awarded by the Association of Innovative Entrepreneurship of the Czech Republic.

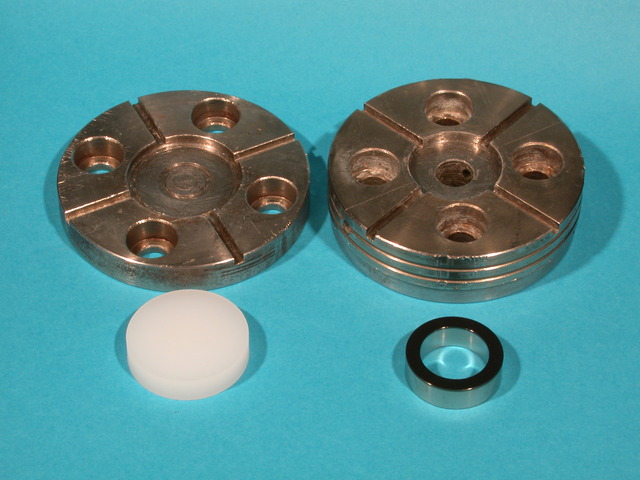

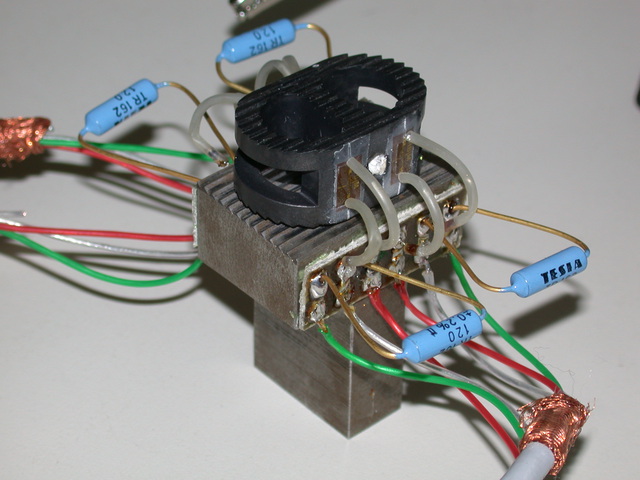

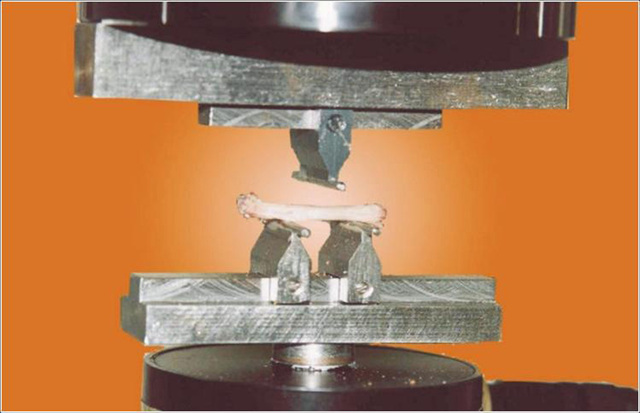

Within the scope of non-accredited tests, the Mechanical Testing Laboratory performes tests on biomaterials and implants. Examples include: C-C composite materials, dental materials, UHMWPE (wear resistance, Figure 4a), intervertebral implants (Figure 4b), hip and knee replacements, mitral implants (Figure 4c). A further group of tests is on biological materials and on determining their mechanical properties, e.g. tensile tests of the cornea or the arterial wall, bending tests on osteoporotic rat femurs (Figure 5a and 5b), mechanical tests on spinal segments (Figure 5c), compression tests on articular cartilage, and also tests on classic metallic materials in static and dynamic loading.

The Mechanical Testing Laboratory is continuously modernized and extended with new equipment and gauges that increase its scope for cooperating not only with other institutes in research projects, but also for commercial collaboration. In future, other testing methods can be improved and accredited that will extend the services offered by MTL on the Czech and European market, and will raise the prestige not only of MTL, but also of the Czech Technical University in Prague as a whole.

Cooperation:

1. LF UK + FN Na Bulovce; III. Internal clinic VFN; VÚS VFN, Medin, a.s.; Medin Orthopaedics, a.s.; Beznoska, s.r.o.; LASAK, s.r.o.; ProSpon, spol. s.r.o.; Erilens, s.r.o.

Projects in realisation

- Research of technical and biological composite materials

- Relationship between blood vessel wall architecture and constitutive behavior

- Influence of inhomogeneities on the mechanical behavior of blood vessels - bifurcations

- The corrosive potential as a marker of endoprosthesis failure

- Biotribology of joint replacements

- Wear of thumb joint replacement

- Constitutive modeling of blood vessels

- Indentor instrument for cartilage stiffness measurement

- Numerical Analyses and Experimental Testing of Dental Implants

- Experimental measurement of the lumbar spine kinematics

- Pull out tests of the spinal screws

- Influence of mechanical loading on the onset and development of hip joint osteoarthritis

- Endurance Test of Stemmed Femoral Component of Total Hip Replacement

- Structural computational and experimental analysis of spinal fixators

- High Performance Radiolucent Composite Materials Providing High Resistance against Sterilization Decomposition, for use in Medicine

- Porous Composite Materiáls with Polyamide Reinforcement and Siloxane Matrix with Nano-Hydroxyapatite as Biomaterials

- Long Bone Reconstruction and Periprosthetic Fractures Using the Osteosynthesis Materials and the Operation Procedures - Trauma I

- Inovation of French Crutches

- Mechanical properties of osteoporotic bones